In search of breakthroughs in Industry 4.0 Manufacturing Systems

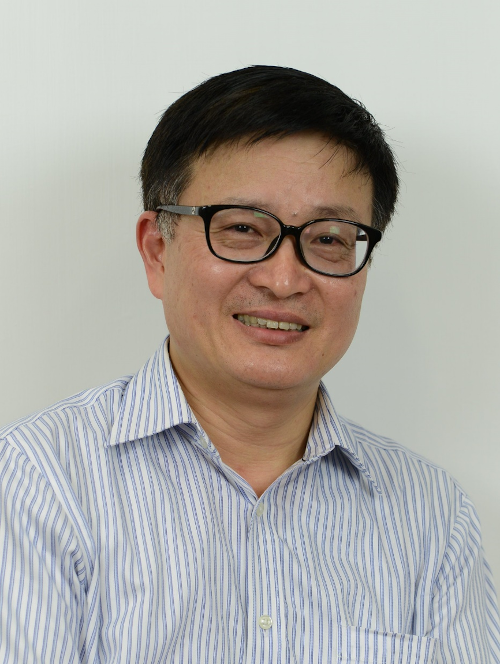

George Q. Huang

Chair Professor and Head of Department

Department of Industrial and Manufacturing Systems Engineering,

The University of Hong Kong

ABSTRACT

Industry 4.0 has been considered as the fourth industrial revolution. If it is a revolution, it mandates novel breakthroughs. This talk takes another dimension in addition to Automation Artificial Intelligence and Robotics (AIR dimension), which are considered as powerful weapons for this revolution. This dimension focuses on three novel breakthroughs to enable this revolution to come true.

The first breakthrough is “Finite element cyber-physical digitization.” A factory is decomposed into finite elements (physical twins) of man, machine and material for most cost-effective creation of corresponding digital twins through industrial wearables. Physical and digital twins, called cyber-physical holons, and their interactions and interoperability are captured through cyber-physical visibility and traceability. This breakthrough significantly innovates a method for systematically digitizing Industry 4.0 factories.

The second novel breakthrough is “Theory of spatiotemporal Uncertainty Postponement (TUP).” Automation of some degree is essential in Industry 4.0 factories. It is well-known that automation is vulnerable to uncertainties and unforeseen disturbances including stochastic order arrivals and machine breakdowns. This is particularly serious when a relatively large “spatiotemporal window” is used, e.g. time horizons for production planning or scheduling across the entire shopfloor or production lines. This theory proposes to delay the consideration of uncertainties related to finite-element cyber-physical holons at the current spatiotemporal widow to the next widow. This ensures that decision models of the holons at the current spatiotemporal widow are deterministic and simple, and their dependencies with the next spatiotemporal widow are fully established by cyber-physical visibility & traceability analytics. The theory seeks to maximize the value and minimize the loss of postponing uncertainties.

The third breakthrough is “Spatiotemporal Analytics for Synchronization (SAS).” Production planning, scheduling and execution have been widely researched and solutions have been commercially available through enterprise resource planning (ERP) and manufacturing execution systems. However, underlining methods and theories suffer from uncertainties and NP-hardness, and they seldom use cyber-physical visibility and traceability of Industry 4.0 factories. Data-driven mechanisms would be investigated for cyber-physical synchronization, holonic synchronization and spatiotemporal synchronization. Not only punctuality but also simultaneity will be considered and built into decision models for cyber-physical factory planning, scheduling and execution.

Both dimensions complement with each other and together they govern what and how Industry 4.0 manufacturing systems are realized and operated.

SPEAKER BIO

Dr George Q. Huang is Chair Professor and Head of Department in Department of Industrial and Manufacturing Systems Engineering, The University of Hong Kong. He gained his BEng and PhD in Mechanical Engineering from Southeast University (China) and Cardiff University (UK) respectively. He has conducted research projects in the field of Physical Internet for Manufacturing, Logistics and Construction with substantial government and industrial grants exceeding HK$50M. He has published extensively including over three hundred refereed articles in journals and conferences in addition to ten monographs, edited reference books and conference proceedings. He is among “Top 1% Most Cited Scholar” in the relevant field. He serves as associate editors and editorial members for several international journals. He is a Chartered Engineer (CEng), a fellow of ASME, HKIE, IET and CILT, and member of IIE and HKLA.